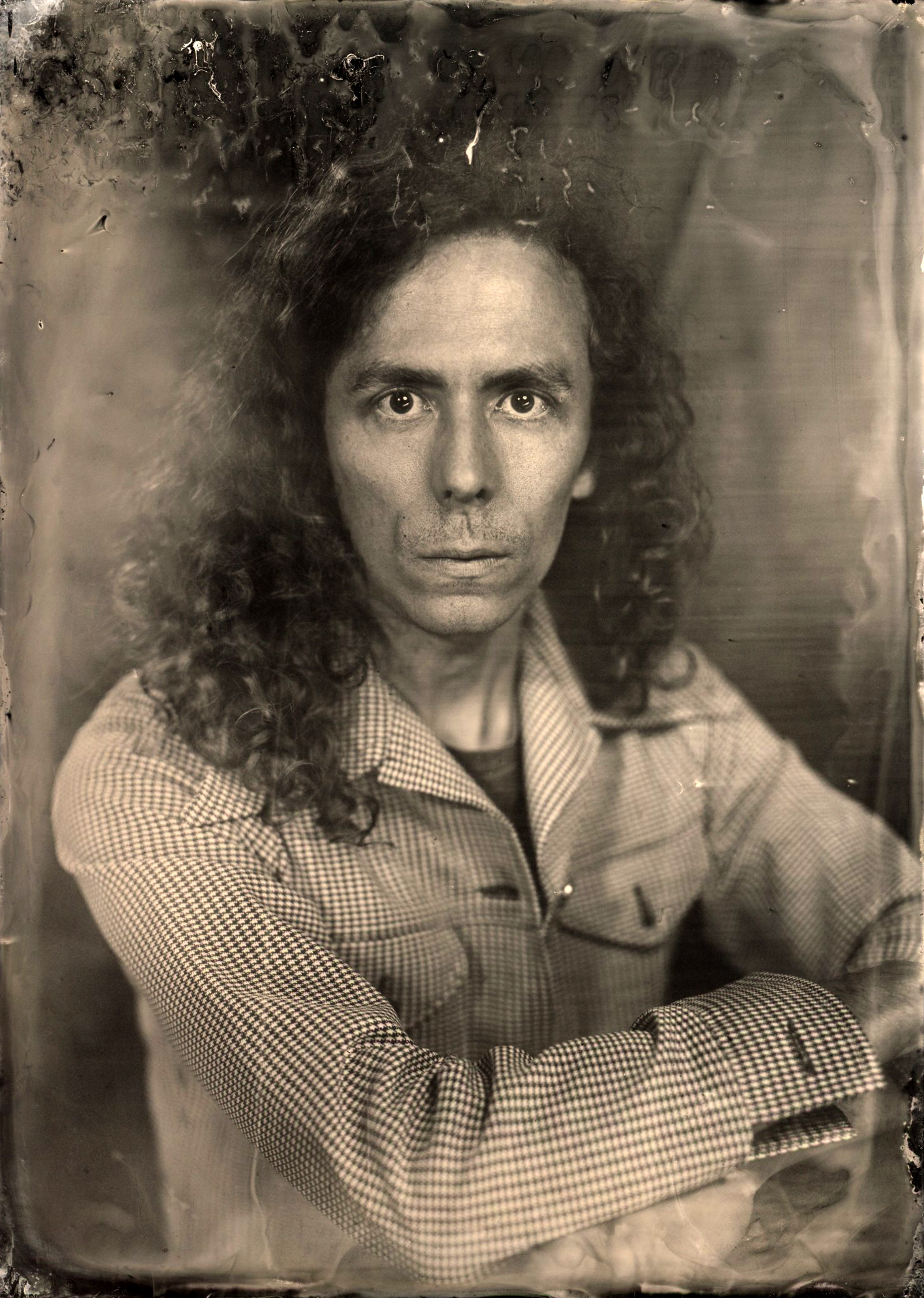

Cleaning Glas Plates with Ultrasound

Achieving pristine cleanliness for collodion plates with ultrasonic cleaning

The wet-plate collodion process is an art that demands perfection. You can have the best chemicals and a perfect darkroom, but if your glass plate isn't chemically and physically pristine, you will see poor results. Streaks, blemishes, and coating failures can almost always be traced back to residual grease, oil, or dust.

While the traditional polishing methods are non-negotiable for the final surface preparation, the ultrasonic cleaner offers a powerful and efficient way to handle the bulk and pre-cleaning, especially for reusing plates or preparing new, dirty glass.

DIY Ultrasonic Cleaning Solution for Collodion Plates

The ideal solution must be a strong degreaser that is highly volatile and leaves no surfactant residue behind. Here is the recommended recipe for the ultrasonic bath:

| Ingredient | Concentration (by Volume) | Function |

| Destilled Water | 98% | The solvent; prevents mineral/salt deposits which cause streaks and fogging. |

| Ammonia NH3 | 2% | Powerful alkali; effectively saponifies (converts) and dissolves organic oils, grease, and fingerprints. |

Chemical Interactions and Critical Warnings

1. The Role of Ammonia as a Degreaser

Ammonia NH3 works as a strong degreaser by creating an alkaline environment (Ammonium Hydroxide).

Saponification: It reacts with fatty acids left by fingerprints, turning them into water-soluble compounds (soaps).

Volatile Nature: Crucially, ammonia is highly volatile. This means it turns to gas quickly and, with proper rinsing, should leave zero residual film on the glass surface. This is its key advantage over common household soaps (surfactants), which are designed to adhere to surfaces.

2. Chemical Interaction with Collodion

It is absolutely essential that the glass is completely free of ammonia before the collodion is poured and the plate is placed in the silver bath.

Base vs. Acid: The collodion process relies on a slightly acidic environment, particularly in the silver nitrate bath.

The Reaction: If residual ammonia is present on the plate when it enters the silver bath, the basic ammonia will react with the silver nitrate. This can cause the formation of Silver Oxide or precipitates.

The Result: These silver compounds will precipitate onto the glass surface, leading to chemical fogging, streaks, patchy development, and poor image quality.

The ultrasonic cleaning process must be followed by a manual final cleaning.

Step 1: Ultrasonic Bulk Cleaning

Preparation: Mix the 2% ammonia in deionized water (e.g., 20 ml of 10% household ammonia per 1 liter of destilled water).

Soak & Run: Place the plates in the ultrasonic bath. Run the cleaner for 10-20 minutes, which uses cavitation to lift residues and dirt from the plate surface and edges.

Critical Rinse: Remove the plates and power-rinse immediately under running deionized or distilled water for several minutes to wash away all traces of the ammoniated solution.

Step 2: Traditional Final Polish

The ultrasonic bath handles the bulk cleaning, but the absolute clean surface required for collodion adhesion must be achieved manually.

Polishing: Prepare a traditional abrasive (e.g., using a fine abrasive powder like White Chalk mixed with denatured Ethanol).

Vigorous Scrubbing: Using a dedicated cloth, scrub the plate vigorously and uniformly to mechanically remove the last layer of surface molecules. This step ensures optimal plate tooth and adhesion.

Final Rinse: Rinse the plate one last time with fresh water just before drying and pouring the collodion.

By combining the degreasing of the ultrasonic cleaner with the precision of the traditional final polish, you can achieve the chemically perfect surface that the wetplate collodion process demands.